Single Item vs Multi Item Batch Picking: A Complete Guide

Discover how efficient batch picking processes can reduce warehouse labor costs by up to 50%. Learn which method best suits your operation.

Understanding Batch Picking Fundamentals

Batch picking is the process of picking items for multiple orders simultaneously. By grouping orders into batches, pickers can minimize their trips through the warehouse, which streamlines operations and reduces non-value-added activities like walking back and forth between shelves.

💡 Key Insight

The way orders are batched significantly affects the efficiency of the process. Choosing the right method can lead to dramatic improvements in productivity and accuracy.

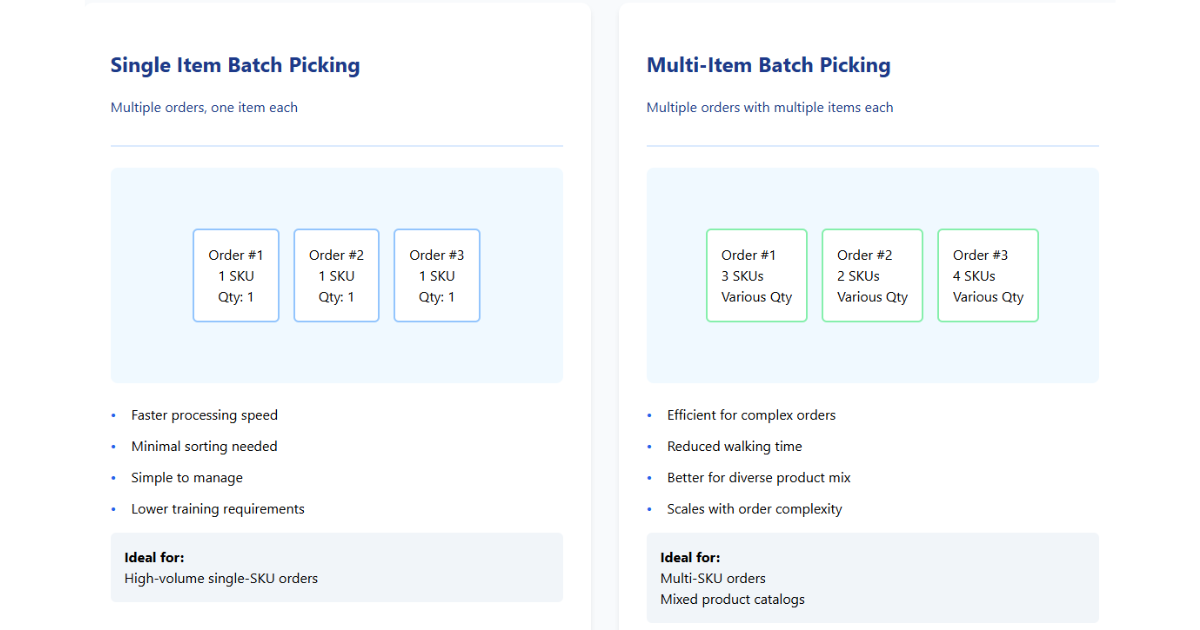

Single Item Batch Picking

Single Item Batch: Multiple Orders, Each Following 1-1 Rule

Multiple Orders

Batch multiple orders together

1 Line Item Per Order

Each order contains exactly one SKU

Quantity of 1

Each line item has quantity of one

Single Item Batch Picking combines multiple orders, where each order follows the 1-1 rule: one line item with a quantity of one

Single Item Batch Picking is designed specifically for orders with just one line item and a quantity of one. In this method, all items for single-item orders are collected in a single tote or cart. This process is particularly effective for high-volume businesses that frequently process orders containing individual SKUs.

Multi-Item Batch Picking

Multi-Item Batch Picking Process

Multiple Orders

Process several orders simultaneously

Multiple Items

Pick various SKUs in one trip

Multiple Quantities

Handle different quantities per item

Multi-Item Batch Picking involves collecting items for multiple orders, each containing multiple SKUs. Each order is assigned to a unique tote, and the system guides the picker to select the appropriate quantity of items for each order.

Summary Comparison